ALL KINDS OF TURNNING, MILLING, DIECUTTING AND GLUE DISPENSING JOB WORKS

At Karuppasamy Engineering Works, our mission is simple yet profound: to bring precision to every detail of our turning, milling, die cutting and glue dispensing job work services. We are driven by the belief that precision is not just a standard but a necessity in today’s competitive world. We strive to be the reliable partner our clients can trust for the most intricate projects.

DIE CUTTING JOB WORK

The Swing Arm Clicker Press is useful for a wide variety of die cutting applications. The most common uses are cutting soft to semi-rigid materials. For example, ITO films, gaskets, leather, rubber, elastic, foam and other like materials

OUR COMPANY MANUFACTURING PRODUCT

All kinds of turning and milling works, general machine mainteance works, all kinds of jig, fixture, gauges and toolroom works, general engineering appliances all kinds of moulding department work like extruder die, pin etc

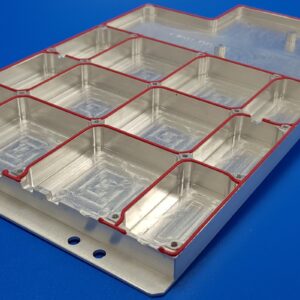

FORM IN PLACE FIPG GASKETS

The form in place gasket or dispensed gasket application process precisely guides a fluid dispensing nozzle under CNC control to enable the continuous application of intricate, small cross-section gaskets (0.35 – 2.0mm) directly onto the contours of a component or substrate.

The main advantages of the form in place process are:

● Materials resistant to oils and fuels available

● Very low material waste

● Complex labyrinthine gaskets may be accurately and efficiently applied

● Rapid prototyping – a seal may be applied to an SLA for testing usually within a few days

● Very short process lead times

● Minimal or no initial tooling costs

● Gasket design changes easily implemented

● Variable height and width gaskets may be produced

● Effective EMI and environmental (or combination) seals can be achieved in restricted space

● A variety of materials may be selected to optimise performance

The form in place gasket material selection will depend on the nature of the application but will generally consist of a silicone elastomer loaded with electrically conductive particles for EMI shielding gaskets and non-conductive RTV silicones for purely environmental seals. Our range of fluorosilicones can provide a high resistance to oils, fuels and other organic contaminants. This makes it better suited for automotive or pharmaceutical applications.

At Shielding Solutions we produce our own form in place gasket material compounds thus giving us the capability to customise a material’s characteristics to suit the specific performance requirements of any application.

The applied form in place gasket material cures and adheres ‘in-situ’ at room temperature to form a resilient and reusable EMI / environmental seal. The absence of heat makes the process particularly suitable for use with plastic housings or heat sensitive components.

Normally, parts to be processed will be ‘free issued’ by the customer however, at Shielding Solutions we have the expertise and experience to offer a complete service whereby all stages of manufacture of a component may be managed by us to deliver the finished article.

We recognise the importance of providing ‘best practice’ advice for design and material selection during the all important development phase of new projects. This is supported by our rapid sample/prototyping service and follow on production that is geared to assist customers in meeting critical deadlines.

CERTIFICATION